At a glance

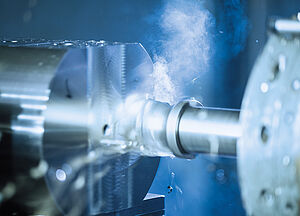

Before you learn about the qualitative aspects of stainless steel processing, would you first like to reassure yourself that we are actually able to produce the parts you need? We are more than happy to provide you (below) with the performance capabilities, inclusive of diameters and lengths, of our CNC turning, milling processes and additive manufacturing. In addition to this, we have produced a list of the materials with which the team at Jung & Co. is familiar and work with on a regular basis.

Performance capabilities

5-axis turning-milling:

- Turn mill complete machining

- Turning and milling length from 2 meters to Ø 700 mm

Turning processes:

- Individual parts and series from Ø 10 to 350 mm

- Component parts can be reliably turned in diameters of up to 310 mm (with the assistance of a bezel) and lengths of 1500 mm.

- We also make use of X and Y axes, meaning that complex processes can be performed on turned parts.

Milling processes:

- Vertical machining centres with rotary tables can cope with and process component parts up to 1400x550x500 mm.

- On our horizontal milling centres we can produce component parts up to 1000x1000 mm.

- 5-axle processing up to 1000x1000 mm is equally possible.

Additive manufacturing / 3D printing:

Capability characteristics:

Multi-laser system M2 (manufacturer: CONCEPTLASER)

Power: 2x400 W

Processing range: 250x250x280 mm (x, y, z)

Materials that can be processed:

- Stainless steel

- Titanium

- Aluminium

- Steel (including tool steel)

3D coordinates measurement:

- Quality assurance complying with the solids provided by the customer because this data is also used as the basis of the measuring program (particularly well suited to free-form surfaces).

- Component parts up to 900x1000x870 mm are measured

- Software modules currently used: MCOSMOS - 3. V4.0, Geopak, CAD 1000P / CAD 1000S, Scanpak

Materials:

- Stainless steel in all standard alloys as well as a variety of special alloys.

- Aluminium in diverse alloys.

- High-strength materials such as Hastelloy, Inconel, Incoloy, Monel, etc.

- As a matter of course, we can also process materials such as brass, copper and most kinds of steel (except for grey cast iron).